Summary of Position

This position will have direct responsibility for the set-up and manufacture of components within a machining Department. TOMZ manufactures parts via high precision metal machining, finishing, assembly, and anodize processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, setup and operate equipment, and perform visual and dimensional inspections on machined components.

Essential Functions

- Must be knowledgeable of, and adhere to, the TOMZ Quality Management System.

- Ability to operate and maintain production on equipment within the department. Ex. include Citizen Lathes, Tsugami Lathes, Index multi-spindle lathes, Willemin Mill turns, various 3-4-5 axis mills, Anodize/Passivation Lines.

- Demonstrated ability to perform offsets and change tools to maintain efficient production with minimal support.

- Ability to efficiently set up complex legacy components and complex new production orders and ensure the machine is ready for steady production.

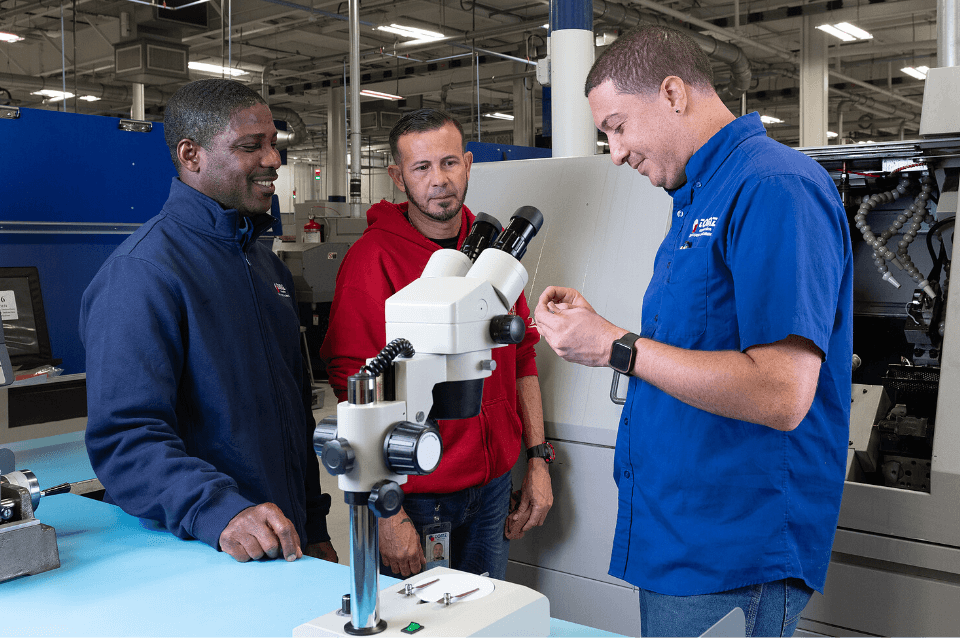

- Perform visual and dimensional inspections on manufactured components, as required using microscope, micrometer, caliper, pin gages, thread gages, comparator, micro-hite, CMM, vision system, etc.

- Regularly and as prescribed, perform preventive maintenance of equipment.

- Lead and train on problem solving activities for complex machine or process issues.

- Completes and compiles necessary documentation related to Quality Inspection standards.

- Ensure proper material control, identification and traceability is maintained for conforming and nonconforming material through the manufacturing processes.

- Lead and train on Quality Best Practices and GDP/GMP continuous improvement efforts.

- Utilize and navigate ERP and QMS systems to ensure inspection and traceability activities are properly documented and controlled, as needed.

- Fit and assemble parts into complex assemblies when required.

- Perform Zeiss (or similar) CMM Gage R&R activities for NPI.

- Perform all AQL data needed when running production with all data entered to the ERP system.

- Perform Qualification runs on NPI to the customers specifications.

- Perform 1st article inspection with minimal support.

- Provide guidance and training to Machinists level I, II & III.

- Perform FANUC (or similar) robot adjustments on basic programs.

- Must maintain safe working conditions and follow occupational Safety and Health requirements including Personal Protective Equipment (PPE) guidance and rules.

- Other duties and responsibilities are assigned.

Qualifications:

Education

- Certification from a Machine trades technical school program, or equivalent directly transferrable work experience (Manufacturing or Engineering discipline preferred).

Experience

- Certification from a Machine trades technical school program and ten years relevant work experience in a regulated medical manufacturing environment, or fifteen years in a regulated medical manufacturing environment.

Qualifications

- Class I, II and/or III Medical Device manufacturing experience.

- Knowledge of and experience with GMP/ISO standards.

- Advanced understanding of the usage and care of mechanical equipment and inspection processes.

- Ability to use hand-held tools to perform preventive maintenance or repair activities and install or change tools.

- Experience editing programs through machine controls.

- “Hands-on” self-starter with ability to work both independently and as part of a team.

- Ability to effectively read and understand blueprints, specifications, GD&T, and procedures.

- Maintains accuracy and attention to detail at all times and completes tasks in a timely manner.

- Ability to work with a variety of functional areas, including R&D, Manufacturing, and QA, as required, accomplishing results with minimal guidance.

Preferred Skills

- Intermediate skills with Microsoft Excel and Word

- Strong verbal and written English language communication skills.

Pay Range: $30 - $38 an hour

Summary of Position This position will have direct responsibility for the set-up and manufacture of components within a machining Department. TOMZ manufactures parts via high precision metal machining...

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive compensation and excellent benefits, including 401k, health/dental, vision, and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and certified to ISO 13485.

Summary of Position

Reporting to the Operations Supervisor, this position will have direct responsibility for the set-up and manufacture of components within the Swiss machining department. TOMZ manufactures parts via high- precision metal machining, finishing, assembly, and anodizing processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, set up and operate equipment, and perform visual and dimensional inspections on machined components using various precision measuring equipment.

Essential Functions

- Operate and maintain Citizen Lathes, Tsugami Lathes, Index multi-spindle lathes, 3-4-5 axis production equipment, including Robo Drills, Mill Turn, and horizontal/vertical mills.

- Perform offsets and tool changes to ensure efficient production with minimal support.

- Set up complex legacy components and new production orders for steady machine operation.

- Conduct visual and dimensional inspections using microscopes, micrometers, calipers, pin gauges, thread gauges, comparators, Micro-Hite, CMM, and vision systems.

- Perform scheduled and regular preventive maintenance on equipment.

- Drive problem-solving activities for complex machine or process issues.

- Complete and compile documentation related to quality inspection standards.

- Ensure proper material control, identification, and traceability for conforming and nonconforming materials.

- Support Quality Best Practices and contribute to continuous improvement in GDP/GMP.

- Capable of mentoring and training lower-level machinists.

- Facilitate a continuous improvement in culture and ensure quality and delivery objectives are met.

- Utilize ERP and QMS systems to document and control inspection and traceability activities.

- Maintain safe working conditions and follow occupational safety and health requirements, including PPE guidance.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Education

- Certification from a technical school program or equivalent, directly transferable work experience in a manufacturing or engineering discipline may be accepted.

- Certification from a technical school program is strongly preferred.

Experience

- Minimum of 3-7 years’ experience in a regulated manufacturing environment.

Qualifications

- Experience in Class I, II, and/or III medical device manufacturing within a regulated environment using calibrated equipment and hazardous materials.

- Relevant job experience in regulated manufacturing, with industry experience in aerospace, defense, or automotive.

- Knowledge of and experience with GMP/ISO standards.

- A self-starter capable of working independently and as part of a team, with the ability to collaborate across various functional areas, including R&D, Manufacturing, and QA, to achieve results with minimal guidance.

- Advanced understanding of mechanical equipment usage, care, and inspection processes.

- Ability to use hand-held tools for preventive maintenance, repairs, and tool changes.

- Skilled in reading and understanding of blueprints, specifications, and procedures.

- Detail-oriented with the ability to maintain accuracy and complete tasks promptly.

- Proficient in identifying nonconformances and maintaining organization.

- Intermediate skills in GD&T.

Preferred Skills

- Strong verbal and written English language communication skills.

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Perform repetitive hand and arm movements while lifting up to 20 pounds, including gripping, twisting, and placing components for extended periods, and lifting objects overhead.

- 20/20 vision (assisted or unassisted) required for sorting raw and non-conforming materials. Good dexterity is needed for managing small to medium products.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Ability to sit or stand for prolonged periods.

WEEKEND SHIFT: 20% DIFFERENTIAL 5AM-5PM FRI-SUN

2ND SHIFT: 15% DIFFERENTIAL 5PM-3:30AM

1st shift- No differential

Pay range: $31.00-$37.00

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive com...

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive compensation and excellent benefits, including 401k, health/dental, vision, and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and certified to ISO 13485.

Summary of Position

Reporting to the Operations Supervisor, this position will have direct responsibility for the set-up and manufacture of components within a machining Department. TOMZ manufactures parts via high- precision metal machining, finishing, assembly, and anodizing processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, set up and operate equipment, and perform visual and dimensional inspections on machined components using various precision measuring equipment.

Essential Functions

- Set up and operate and maintain Citizen Lathes or Tsugami Lathes

- Perform offsets and tool changes to ensure efficient production with minimal support.

- Set up legacy components and new production orders for steady machine operation.

- Perform preventative maintenance on Swiss Lathe to ensure consistent machine performance

- Conduct visual and dimensional inspections using microscopes, micrometers, calipers, pin gauges, thread gauges, comparators, Micro-Hite, CMM, and vision systems.

- Perform scheduled and regular preventive maintenance on equipment.

- Drive problem-solving activities for complex machine or process issues.

- Complete and compile documentation related to quality inspection standards.

- Ensure proper material control, identification, and traceability for conforming and nonconforming materials.

- Support Quality Best Practices and contribute to continuous improvement in GDP/GMP.

- Utilize ERP and QMS systems to document and control inspection and traceability activities.

- Maintain safe working conditions and follow occupational safety and health requirements, including PPE guidance.

Qualifications:

Education/Experience

- High school diploma, GED, or equivalent directly transferrable work experience (Manufacturing or Engineering discipline preferred).

- Certification from a technical school program preferred.

- Minimum of 2-5 years’ experience in a regulated manufacturing environment.

Qualifications

- Experience in Class I, II, and/or III medical device manufacturing within a regulated environment using calibrated equipment and hazardous materials.

- Strong math background, preferable in machine math/shop math

- Relevant job experience in regulated manufacturing, with industry experience in aerospace, defense, or automotive.

- Knowledge of and experience with GMP/ISO standards.

- A self-starter capable of working independently and as part of a team, with the ability to collaborate across various functional areas, including R&D, Manufacturing, and QA, to achieve results with guidance.

- Understanding of mechanical equipment usage, care, and inspection processes.

- Ability to use hand-held tools for preventive maintenance, repairs, and tool changes.

- Effectively read and understand blueprints, specifications and procedures.

- Understanding of GD&T.

- Detail-oriented with the ability to maintain accuracy and complete tasks promptly.

- Identify nonconformances and maintain organization.

Preferred Skills

- Strong verbal and written English language communication skills.

Physical Requirements

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Perform repetitive hand and arm movements while lifting up to 20 pounds, including gripping, twisting, and placing components for extended periods, and lifting objects overhead.

- 20/20 vision (assisted or unassisted) required for sorting raw and non-conforming materials. Good dexterity is needed for managing small to medium products.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Ability to sit or stand for prolonged periods

1st shift: 6AM-2:30PM

2nd shift: 5PM-1:30AM (15% SHIFT DIFFERENTIAL)

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive com...

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive compensation and excellent benefits, including 401k, health/dental, vision, and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and certified to ISO 13485.

Summary of Position

Reporting to the Operations Supervisor, this position will have direct responsibility for the set-up and manufacture of components within the Swiss machining department. TOMZ manufactures parts via high- precision metal machining, finishing, assembly, and anodizing processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, set up and operate equipment, and perform visual and dimensional inspections on machined components using various precision measuring equipment.

Essential Functions

- Operate and maintain Citizen Lathes, Tsugami Lathes, Index multi-spindle lathes, 3-4-5 axis production equipment, including Robo Drills, Mill Turn, and horizontal/vertical mills.

- Perform offsets and tool changes to ensure efficient production with minimal support.

- Set up complex legacy components and new production orders for steady machine operation.

- Conduct visual and dimensional inspections using microscopes, micrometers, calipers, pin gauges, thread gauges, comparators, Micro-Hite, CMM, and vision systems.

- Perform scheduled and regular preventive maintenance on equipment.

- Drive problem-solving activities for complex machine or process issues.

- Complete and compile documentation related to quality inspection standards.

- Ensure proper material control, identification, and traceability for conforming and nonconforming materials.

- Support Quality Best Practices and contribute to continuous improvement in GDP/GMP.

- Capable of mentoring and training lower-level machinists.

- Facilitate a continuous improvement in culture and ensure quality and delivery objectives are met.

- Utilize ERP and QMS systems to document and control inspection and traceability activities.

- Maintain safe working conditions and follow occupational safety and health requirements, including PPE guidance.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Education

- Certification from a technical school program or equivalent, directly transferable work experience in a manufacturing or engineering discipline may be accepted.

- Certification from a technical school program is strongly preferred.

Experience

- Minimum of 3-7 years’ experience in a regulated manufacturing environment.

Qualifications

- Experience in Class I, II, and/or III medical device manufacturing within a regulated environment using calibrated equipment and hazardous materials.

- Relevant job experience in regulated manufacturing, with industry experience in aerospace, defense, or automotive.

- Knowledge of and experience with GMP/ISO standards.

- A self-starter capable of working independently and as part of a team, with the ability to collaborate across various functional areas, including R&D, Manufacturing, and QA, to achieve results with minimal guidance.

- Advanced understanding of mechanical equipment usage, care, and inspection processes.

- Ability to use hand-held tools for preventive maintenance, repairs, and tool changes.

- Skilled in reading and understanding of blueprints, specifications, and procedures.

- Detail-oriented with the ability to maintain accuracy and complete tasks promptly.

- Proficient in identifying nonconformances and maintaining organization.

- Intermediate skills in GD&T.

Preferred Skills

- Strong verbal and written English language communication skills.

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Perform repetitive hand and arm movements while lifting up to 20 pounds, including gripping, twisting, and placing components for extended periods, and lifting objects overhead.

- 20/20 vision (assisted or unassisted) required for sorting raw and non-conforming materials. Good dexterity is needed for managing small to medium products.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Ability to sit or stand for prolonged periods.

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive com...

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive compensation and excellent benefits, including 401k, health/dental, vision, and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and certified to ISO 13485.

Summary of Position

Reporting to the Operations Manager, this position will have direct responsibility for the set-up and manufacture of components within the machining Department. TOMZ manufactures parts via high precision metal machining, finishing, assembly, and anodizing processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, set up and operate equipment, and perform visual and dimensional inspections on machine components.

Essential Functions

- Operate and maintain Citizen Lathes, Tsugami Lathes, Index multi-spindle lathes 3-4-5 axis production equipment, including Robo Drills, Mill Turn, and horizontal/vertical mills.

- Perform offsets and tool changes to ensure efficient production.

- Set up complex legacy components and new production orders for steady machine operation.

- Conduct visual and dimensional inspections using microscopes, micrometers, calipers, pin gauges, thread gauges, comparators, Micro-Hite, CMM, vision systems.

- Perform scheduled and regular preventive maintenance on equipment.

- Lead and train in problem solving activities for complex machine or process issues.

- Complete and compile documentation related to quality inspection standards.

- Ensure proper material control, identification, and traceability for conforming and nonconforming materials.

- Lead and train in Quality Best Practices and contribute to continuous improvement in GDP/GMP.

- Utilize ERP and QMS systems to document and control inspection and traceability activities.

- Perform Zeiss (or similar) CMM Gauge R&R activities for NPI.

- Perform all AQL in production with all data being entered into the ERP system.

- Perform Qualification runs on NPI to the customers specifications.

- Perform the first article inspection with minimal support.

- Capable of mentoring and training lower-level machinists.

- Perform FANUC (or similar) robot adjustments on basic programs.

- Maintain safe working conditions and follow occupational safety and health requirements, including PPE guidance.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Education

- Certification from a Machine trades technical school program, or equivalent directly transferrable work experience (Manufacturing or Engineering discipline preferred).

Experience

- Certification from a Machine trades technical school program and ten years relevant work experience in a regulated medical manufacturing environment, or fifteen years in a regulated medical manufacturing environment.

Qualifications

- Experience in Class I, II, and/or III medical device manufacturing within a regulated environment using calibrated equipment and hazardous materials.

- Knowledge of and experience with GMP/ISO standards.

- Advanced understanding of mechanical equipment usage, care, and inspection processes.

- Ability to use hand-held tools for preventive maintenance, repairs, and tool changes.

- A self-starter capable of working independently and as part of a team, with the ability to collaborate across various functional areas, including R&D, Manufacturing, and QA, to achieve results with minimal guidance.

- Proficient reading and understanding of blueprints, specifications, and procedures.

- Detail-oriented with the ability to maintain accuracy and complete tasks promptly.

- Proficient in identifying nonconformances and maintaining organization.

- Advanced skills in Excel and Microsoft word.

- Strong verbal and written English communication skills.

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Perform repetitive hand and arm movements while lifting up to 20 pounds, including gripping, twisting, and placing components for extended periods, and lifting objects overhead.

- 20/20 vision (assisted or unassisted) required for sorting raw and non-conforming materials. Good dexterity is needed for managing small to medium products.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Ability to sit or stand for prolonged periods.

Job Features

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive com...

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive compensation and excellent benefits, including 401k, health/dental, vision, and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and certified to ISO 13485.

Summary of Position

Reporting to the Operations Supervisor, this position will have direct responsibility for the manufacturing of components through various basic functions within the Department. TOMZ manufactures parts via high precision metal machining, finishing, assembly, and anodizing processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, operate equipment, and perform visual and dimensional inspections on machine components.

Essential Functions

- Operate and maintain 3-4-5 axis production equipment, including Robo Drills, Mill Turn, and horizontal/vertical mills. Citizen Lathes, Tsugami Lathes, Index multi-spindle lathes.

- Perform visual and dimensional inspections on manufactured components, as required using a microscope, micrometer, caliper, pin gauges, thread gauges, comparator, Micro-Hite, etc.

- Support problem-solving activities for complex machine or process issues.

- Complete and compile documentation related to quality inspection standards.

- Ensure proper material control, identification, and traceability for conforming and nonconforming materials.

- Support Quality Best Practices and contribute to continuous improvement efforts of GDP/GMP.

- Utilize ERP and QMS systems to document and control inspection and traceability activities.

- Must maintain safe working conditions and follow occupational safety and health requirements including Personal Protective Equipment (PPE) guidance and rules.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Experience

- Minimum of 0-2 years’ experience in a regulated manufacturing environment.

Qualifications

- Basic understanding of the usage and care of mechanical equipment and inspection processes.

- Ability to use hand-held tools for preventive maintenance, repairs, and tool changes.

- Ability to effectively read and understand blueprints, specifications, and procedures.

- Detail-oriented with the ability to maintain accuracy and complete tasks promptly.

- Basic understanding of GD&T.

- Knowledge of GMP/ISO standards.

Preferred Skills

- Class I, II and/or III Medical Device manufacturing experience.

- Regulated manufacturing industry experience (e.g., aerospace, defense, pharmaceutical, etc.).

- Strong verbal and written English language communication skills

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Perform repetitive hand and arm movements while lifting up to 20 pounds, including gripping, twisting, and placing components for extended periods, and lifting objects overhead.

- 20/20 vision (assisted or unassisted) required for sorting raw and non-conforming materials. Good dexterity is needed for managing small to medium products.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Ability to sit or stand for prolonged periods.

2ND SHIFT: 15% DIFFERENTIAL 5PM-3:30AM

1st shift- No differential

Pay range: $21.00 - $27.00 / hr

Job Features

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive com...

Summary of Position

The Assembly Test Technician is responsible for the set up and operation of various presses, fixtures, custom tooling, and measuring equipment used to produce complex finished assemblies from detail components. Understanding of blueprints, inspection reports, fixturing, and precise measuring will be required for daily tasks.

Essential Functions

- Setup and operation of presses, fixtures, and complex equipment.

- Comprehend and interpret drawings and comprehend work instructions.

- Complete inspection reports based off supplied blueprints.

- Proficiency with hand tools, basic assembly techniques, and measuring tools.

- Attention to detail while checking the function of the assembly per drawing requirements.

- Prior work experience in a regulated medical manufacturing environment or other highly regulated industrial manufacturing environment.

- Always maintains accuracy, attention to detail and completes tasks in a timely manner.

- Computer competency in a manufacturing environment.

- All other duties as assigned.

Qualifications:

Education

- High-school diploma or equivalent.

Experience

- 1-3 years’ experience in a manufacturing environment.

Qualifications

- Comprehension of blueprints

- Experience with hand operated tools

- Familiar with measuring equipment

- Maintains accuracy and attention to detail at all times and completes tasks in a timely manner

- Prior experience work experience in a regulated medical manufacturing environment or regulated medical manufacturing environment.

Job Features

Summary of Position The Assembly Test Technician is responsible for the set up and operation of various presses, fixtures, custom tooling, and measuring equipment used to produce complex finished asse...

Summary of Position

Reporting to the Department Manager, this position will have direct responsibility for the processing of parts through various functions within the Department. TOMZ manufactures parts via high precision metal machining, finishing, assembly, and anodize processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, prepare materials to be processed through various operations, and perform basic visual and dimensional inspections on completed components.

Essential Functions

- Prepare and process components through various metal finishing operations.

- Tumbling

- Blasting

- Heat Treat

- Laser Welding

- Laser Marking

- Passivation

- Anodize

- Perform visual and basic dimensional inspections on completed components, as required using micrometers, calipers, microscope, etc.

- Completes and compiles necessary documentation related to Quality Inspection standards.

- Ensure proper material control, identification and traceability is maintained for conforming and nonconforming material through the manufacturing processes.

- Support Quality Best Practices and GDP/GMP continuous improvement efforts.

- Utilize and navigate ERP and QMS systems to ensure inspection and traceability activities are properly documented and controlled, as needed.

- Must follow occupational Safety and Health requirements including Personal Protective Equipment (PPE) guidance and rules.

- Other duties and responsibilities are assigned.

Qualifications:

Education

- High school diploma, GED, or equivalent directly transferrable work experience (Manufacturing or Engineering discipline preferred).

Experience

- Minimum of 0-2 years’ experience in a regulated manufacturing environment.

Qualifications

- Ability to use basic hand-held tools to support preventive maintenance activities.

- Maintains accuracy and attention to detail at all times and completes tasks in a timely manner.

- Strong verbal and written English language communication skills.

- Strong background concerning the usage and care of mechanical metal finishing equipment and processes.

- Must have good organizational skills.

Preferred Skills

- Ability to effectively read and understand blueprints, specifications, and procedures.

- Knowledge of and experience with GMP/ISO standards.

- Regulated manufacturing industry experience (e.g. Aerospace, Defense, Pharmaceutical, etc.)

- Class I, II and/or III Medical Device manufacturing experience

Physical Demands

While performing the duties of this job, the employee is frequently required to sit, talk and/or hear, and/or use hands to finger, handle, or touch objects, tools, or controls. The employee is frequently required to stand, and/or walk. The employee must occasionally lift and/or move up to 50 pounds while moving components or fixtures/racking. The mental and physical requirements described here are representative of those that must be met by an individual to successfully perform the essential functions of this position.

Job Features

Summary of Position Reporting to the Department Manager, this position will have direct responsibility for the processing of parts through various functions within the Department. TOMZ manufactures pa...

Summary of Position

The Senior Human Resources Generalist provides advanced, hands-on HR support across multiple functional areas while serving as a trusted advisor to employees and leadership. This role plays a key part in driving the effectiveness of the Human Resources Department by supporting the Vice President of HR & EHS, providing expert guidance on employee relations and compliance matters, and ensuring consistent application of company policies, procedures, and quality standards across the Connecticut site.

The Senior HR Generalist exercises sound judgment, operates with a high degree of independence, leads complex HR activities, and contributes to the continuous improvement of HR processes, systems, and the overall employee experience.

The Senior HR Generalist will play a key role in supporting day-to-day HR operations while partnering closely with leadership. This position offers the opportunity to take on increasing responsibility and may evolve into an HR Manager role as the organization grows.

Essential Functions

Employee Relations, Compliance & HR Operations

- Serve as a senior-level point of contact for employee relations matters, independently handling complex issues and providing guidance to employees and managers on policies, procedures, performance concerns, and workplace issues.

- Lead and support workplace investigations, including policy violations, misconduct, harassment, and employee complaints; ensure timely, fair, and consistent resolution and documentation.

- Coach leaders on effective employee management practices, corrective action, performance documentation, and conflict resolution.

- Coordinate and lead new hire onboarding to ensure a compliant, engaging, and positive first-day experience, including orientation, badge processing, and documentation verification.

- Prepare, process, audit, and maintain employee lifecycle documentation, including hires, transfers, promotions, status changes, and terminations.

- Ensure all onboarding and personnel documentation is completed accurately and in compliance with legal, regulatory, and internal requirements.

- Maintain Form I-9 compliance, including historical recordkeeping, reverifications, and coordination of updated documentation as required.

- Administer and track employee referral bonus programs and related reporting.

- Conduct regular audits of personnel files and HR records to ensure accuracy, consistency, confidentiality, and compliance.

Performance Management, Talent & Development

- Support and administer performance management processes, including goal setting, performance reviews, corrective action, and employee development planning.

- Partner with leadership to identify training needs and coordinate or deliver HR-related training such as workplace conduct, harassment prevention, and leadership fundamentals.

- Support talent development, internal mobility, and succession planning initiatives as assigned.

- Provide guidance on career development and performance improvement strategies.

Benefits, Communication & Engagement

- Serve as a knowledgeable resource for employees regarding benefit programs, including health insurance, safety footwear, protective eyewear, and company apparel.

- Assist employees with benefit-related questions and enrollment support in coordination with benefits vendors and leadership.

- Prepare, post, and distribute internal communications and maintain employee bulletin boards, wellness displays, and recognition boards.

- Support and help lead employee engagement initiatives, wellness programs, recognition efforts, and company-sponsored events.

- Partner with the Employee Relations Specialist on community outreach initiatives and site-wide programs that support employee morale and company culture.

Safety, Quality & Cross-Functional Support

- Maintain and update OSHA logs in compliance with regulatory requirements.

- Support safety initiatives by partnering with EHS and leadership on documentation, training records, and compliance activities.

- Maintain working knowledge of the TOMZ Quality Management System and ensure HR documentation aligns with quality system requirements.

- Support internal and external audits related to HR, safety, and quality systems as required.

- If bilingual, coordinate and conduct HR, Safety, and Quality System orientations and provide translation support as needed.

HR Systems, Analytics & Continuous Improvement

- Utilize HR systems and data to track trends, support reporting, and provide insights related to turnover, onboarding effectiveness, engagement, and compliance.

- Identify opportunities to improve HR processes, documentation, and workflows to enhance efficiency and the employee experience.

- Assist with HR system implementations, upgrades, and optimization initiatives.

- Develop and maintain standard operating procedures (SOPs) and job aids for HR processes as needed.

Qualifications:

Education

- Bachelor’s degree in human resources, Business Administration, or a related field, or equivalent relevant experience.

Experience

- Minimum of 4 years of progressive experience in a Human Resources Generalist role, with demonstrated ownership of employee relations and compliance activities.

Qualifications

- Demonstrated ability to manage sensitive and confidential matters with discretion, professionalism, and sound judgment.

- Strong working knowledge of HR compliance, employee relations, investigations, and recordkeeping best practices.

- Proficiency with Microsoft Office applications and HR information systems.

- Excellent written, verbal, and interpersonal communication skills.

- Strong organizational skills with exceptional attention to detail.

- Ability to work independently while collaborating effectively with leadership and cross-functional teams.

Preferred Skills

- Highly preferred: Bilingual in Ukrainian and/or Polish

- OSHA reporting and compliance experience

- Experience supporting manufacturing or other regulated environments

- SHRM-CP, SHRM-SCP, PHR, or SPHR certification preferred

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 20 pounds; team lifting or mechanical assistance required for items over 20 pounds.

- Ability to sit for extended periods.

- Proficient use of keyboard and mouse requiring manual dexterity and coordination.

- Ability to focus on computer screens and other visual tasks for prolonged periods, with appropriate vision correction if needed.

- Ability to perform repetitive hand and arm movements

Summary of Position The Senior Human Resources Generalist provides advanced, hands-on HR support across multiple functional areas while serving as a trusted advisor to employees and leadership. This r...

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a Senior Maintenance Machine Specialist to join our organization. TOMZ offers competitive compensation and excellent benefits, including 401k, health/dental, vision, and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and is certified to ISO 13485.

Summary of Position

The purpose of the Senior Maintenance Machine Specialist is to provide production equipment support for all equipment allocated to the Factory as well as to assist engineering with production-related projects. Routinely works with Plant Maintenance to coordinate jobs and projects. The Senior Maintenance Machine Specialist will take the lead in the implementation and the decision-making process on best practices for the maintenance group. The position is also responsible for creating solutions and providing technical support to enhance production reliability through concerted efforts with cross functional teams.

Essential Functions

Duties and responsibilities include, but are not limited to:

- Adherence to all department safety measures and work instructions.

- Accountable for personal safety, the safety of co-workers and promoting a safe work environment.

- Repair and maintain all production equipment, both electrical and mechanical.

- Assist engineering as required with special machine related projects.

- Work with CONC and PLC controlled machines.

- Routinely work in electrical control panels of production equipment to troubleshoot electrical problems.

- Arc Flash certified worker to work “live” electrical control panels.

- Working understanding of precision measuring instruments used in troubleshooting.

- Read and interpret diagrams, schematics and specifications related to equipment operation.

- Monitor, modify, or write programmable ladder logic circuits as needed for existing or new installations.

- Create electrical drawings, PLC programs to be used for troubleshooting of modified equipment.

- Install electrical, air and data drops to equipment and machines.

- Work with outside contractors for equipment repair of production machines as needed and verify completion accuracy.

- Design and implement electrical circuits and technologies for support of production equipment.

- Initiate or enhance the preventative maintenance schedules for production equipment.

- Calibrate equipment using general and special purpose test equipment.

- Facilitate equipment modifications, upgrades, overhauls, and root cause failure analyses.

- Ensure respective area is complaint with 5S Standards.

- Maintain daily log of work in established systems.

- Support ISO 13485 initiatives.

- Assist in training individuals with less experience and tenure on established maintenance standards and practices.

- Project initiation and improvement ideas to better production and the business.

- Purchase repair parts, tools, and supplies in appropriate ERP software.

- Provide input for annual department budget planning.

- Ability to work flexible hours (including overtime) to accommodate production working hours as needed.

- Other duties and responsibilities as assigned.

Qualifications:

Education

- Associate degree in a technical related field or equivalent experience

Experience

- Minimum 10 years’ experience in the Equipment Maintenance Field

Qualifications

- “Hands-on” self-starter with ability to work both independently and as part of a team.

- Maintains accuracy, is detail oriented, and completes tasks in a timely manner.

- Prior experience with CNC and PLC controlled equipment.

- Experience with MS Office Programs.

- Ability to perform routine maintenance of CNC manufacturing equipment; troubleshoot issues and support, or directly resolve as appropriate.

- Ability to read and interpret documents and drawings (e.g., blueprints, manuals, wiring diagrams etc.)

- Time management skills and ability to prioritize workflow throughout the day.

- Strong verbal and written English language communication skills.

Preferred Skills

- Forklift and OSHA Training.

Physical Demands

While performing the duties of this job, the employee is frequently required to sit, talk and/or hear, and/or use hands to finger, handle, or touch objects, tools, or controls. The employee is frequently required to stand, and/or walk. The employee must occasionally lift and/or move up to 50 pounds while moving tooling, fixtures, equipment and/or small packages. The mental and physical requirements described here are representative of those that must be met by an individual to successfully perform the essential functions of this position.

Pay Range: $29.81/hr - $43.75/hr

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a Senior Maintenance Machine Specialist to join our organization. TOMZ offers c...

Our Mission

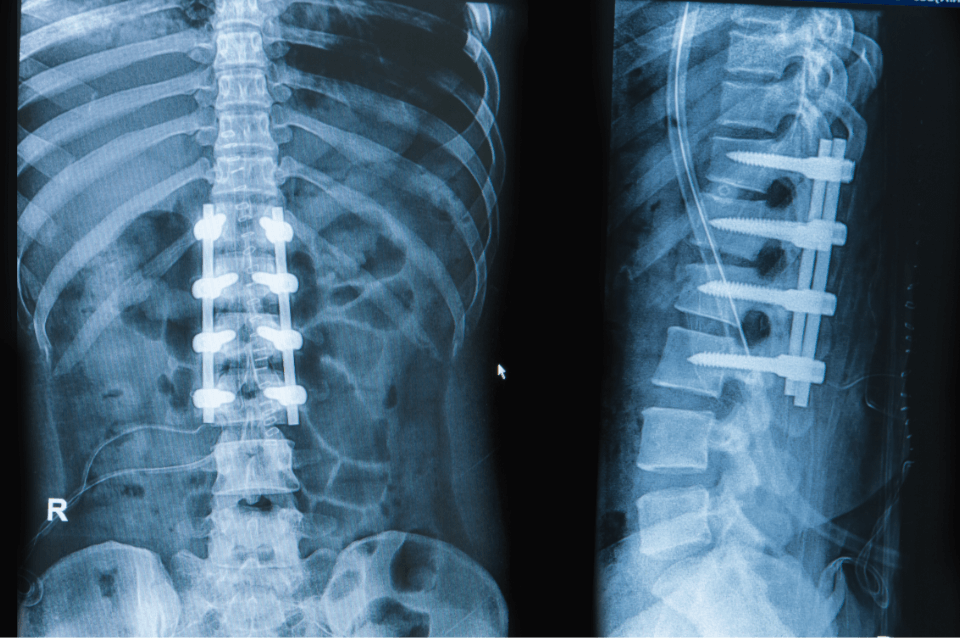

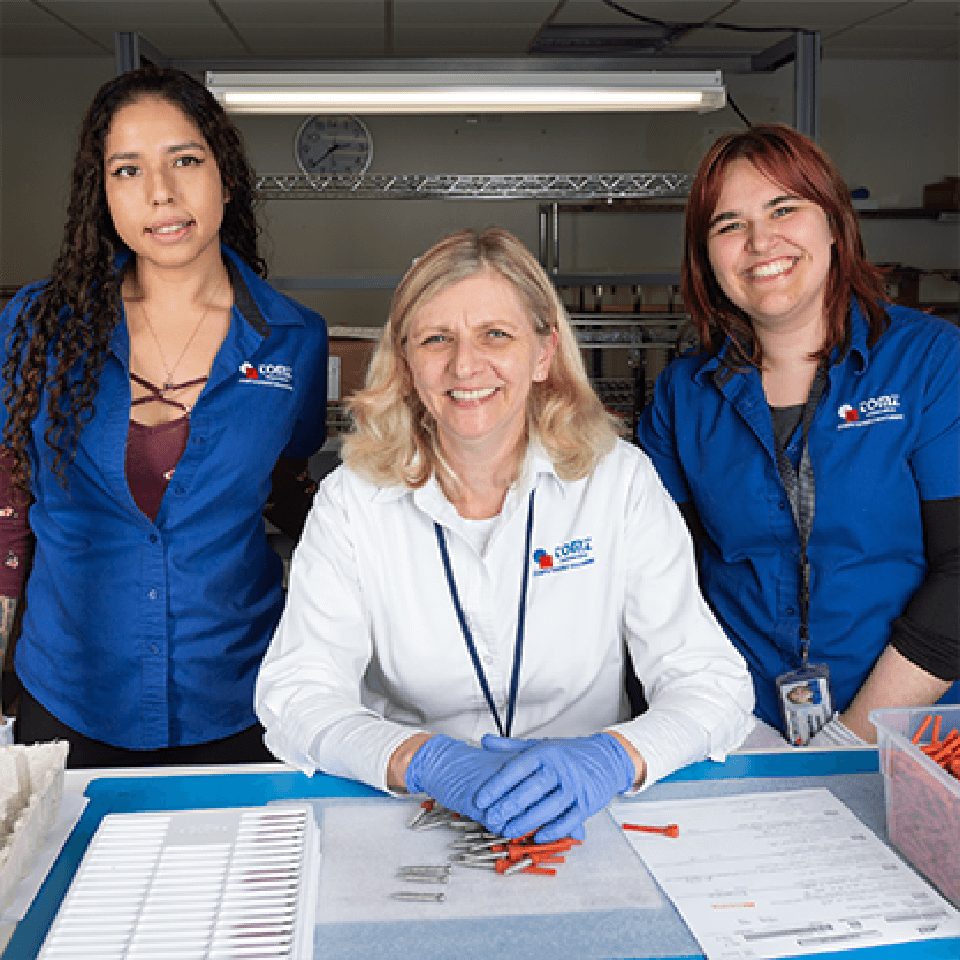

Advancing quality of life by manufacturing medical devices for global healthcare companies.

We Manufacture Medical Devices

We specialize in manufacturing the best medical device implants for medical teams and surgeons around the world. Most of our team will tell you that the work is very fulfilling because we help people live better lives.

Company Values & Culture

Our DNA is as unique as everyone that works here.

Put Patients First

Embrace Diversity

Learn & Grow

Reward Great Effort

Why Work at TOMZ?

We are large enough to offer stability and great benefits, yet small enough to recognize you as an individual and not just “another employee.”

Multiple departments from facilities management to engineering allows you to explore different career paths.

The medical devices industry is experiencing explosive growth with no signs of stopping any time soon.

We have completed our 8th expansion which includes amenities such as locker rooms, showers, an expanded cafeteria, and more.

We have a deep bench of knowledgeable pros to help you.

Everything from 401K to top-of-the-line healthcare, life insurance, and more!

What Our Team Members Have to Say

Playlist

2:37

2:12

Benefits

401(k) Retirement Plan

We will match $0.50 on the dollar up to an 8% contribution. Work with us, retire with us.

Overtime Available

Opportunities to earn overtime hours are available as needed.

Paid Holidays

Enjoy 9 paid holidays off per year.

Paid Time Off (PTO)

PTO starts accruing from the day you start.

Referral Bonus

Employees are eligible to earn a $3,500 referral bonus!

Health Insurance Plans

Enjoy a low employee co-pay with high contributions towards your plan.

Dental Insurance Plans

Yes - we have a great dental plan as well!

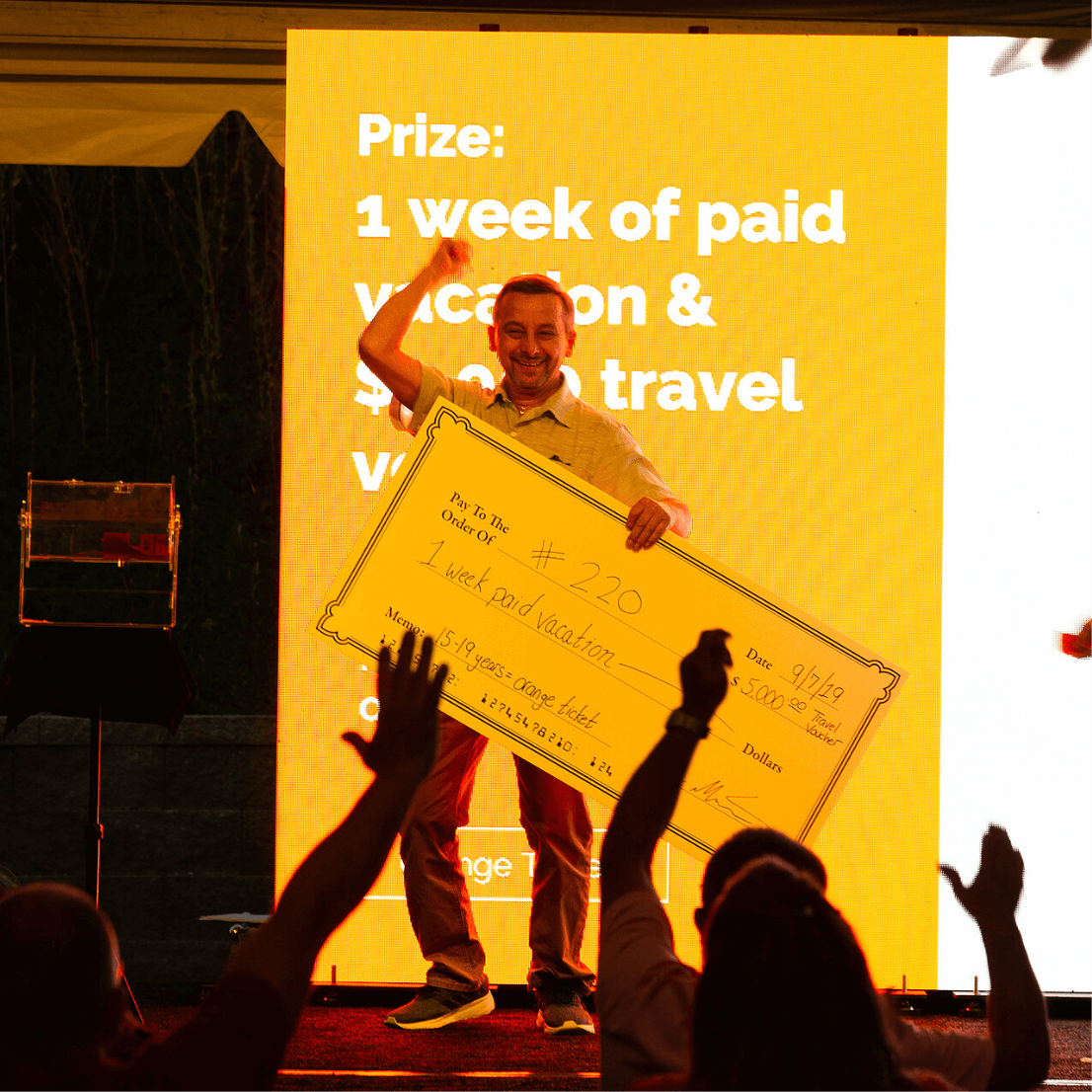

Quarterly Bonus

Teams achieving set performance goals receive a quarterly performance bonus.