Summary of Position

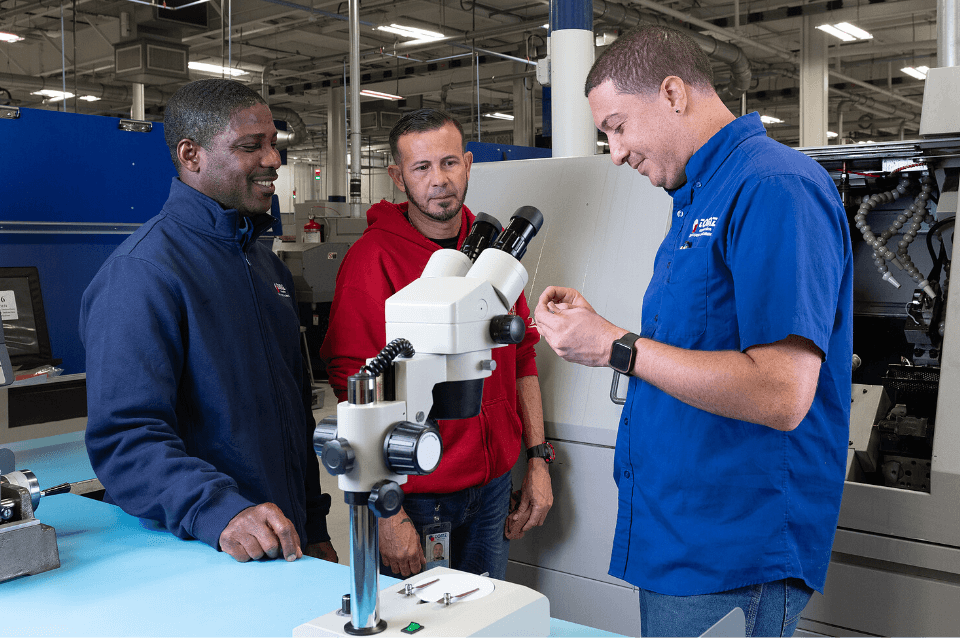

Reporting to Department Manager, this position will have direct responsibility for the setup and manufacture of components within a machining Department. TOMZ manufactures parts via high precision metal machining, finishing, assembly, and anodize processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, setup and operate equipment, and perform visual and dimensional inspections on machined components.

Essential Functions

- Ability to operate and maintain production on equipment within the department. Ex. include Citizen Lathes, Tsugami Lathes, Index multi-spindle lathes, Willemin Mill turns, various 3-4-5 axis mills.

- Demonstrated ability to perform offsets and change tools to maintain efficient production with minimal support.

- Ability to efficiently setup complex legacy components and basic new production orders and ensure the machine is ready for steady production.

- Perform visual and dimensional inspections on manufactured components, as required using microscope, micrometer, caliper, pin gages, thread gages, comparator, micro-hite, CMM, Vision system, etc.

- Regularly and as prescribed, perform preventive maintenance of equipment.

- Drive problem solving activities for complex machine or process issues.

- Completes and compiles necessary documentation related to Quality Inspection standards.

- Ensure proper material control, identification and traceability is maintained for conforming and nonconforming material through the manufacturing processes.

- Support Quality Best Practices and GDP/GMP continuous improvement efforts.

- Utilize and navigate ERP and QMS systems to ensure inspection and traceability activities are properly documented and controlled, as needed.

- Must maintain safe working conditions and follow occupational Safety and Health requirements including Personal Protective Equipment (PPE) guidance and rules.

- Must be knowledgeable of, and adhere to, the TOMZ Quality Management System.

- Other duties and responsibilities are assigned

Qualifications:

Education

- High school diploma, GED, or equivalent directly transferrable work experience (Manufacturing or Engineering discipline preferred).

- Certification from a technical school program strongly preferred.

Experience

- Minimum of 3-7 years’ experience in a regulated manufacturing environment.

Qualifications

- Class I, II and/or III Medical Device manufacturing experience.

- Regulated manufacturing industry experience (e.g. Aerospace, Defense, Pharmaceutical, etc.)

- Knowledge of and experience with GMP/ISO standards.

- Advanced understanding of the usage and care of mechanical equipment and inspection processes.

- Ability to use hand-held tools to perform preventive maintenance or repair activities and install or change tools.

- “Hands-on” self-starter with ability to work both independently and as part of a team.

- Ability to effectively read and understand blueprints, specifications, and procedures.

- Maintains accuracy and attention to detail at all times and completes tasks in a timely manner.

- Ability to work with a variety of functional areas, including R&D, Manufacturing, and QA, as required, accomplishing results with minimal guidance.

Preferred Skills

- Strong verbal and written English language communication skills.

Physical Demands

- Occasionally lift/move up to 50 pounds this may be performed with assistants if needed.

- Prolonged periods of sitting.

Pay Range: $26/hr - $36/hr

Summary of Position Reporting to Department Manager, this position will have direct responsibility for the setup and manufacture of components within a machining Department. TOMZ manufactures parts vi...

Summary of Position

Reporting to the Operations Supervisor, this position will have direct responsibility for the set-up and manufacture of components within the Swiss machining department. TOMZ manufactures parts via high- precision metal machining, finishing, assembly, and anodizing processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, set up and operate equipment, and perform visual and dimensional inspections on machined components using various precision measuring equipment.

Essential Functions

- Operate and maintain Citizen Lathes, Tsugami Lathes, Index multi-spindle lathes, 3-4-5 axis production equipment, including Robo Drills, Mill Turn, and horizontal/vertical mills.

- Perform offsets and tool changes to ensure efficient production with minimal support.

- Set up complex legacy components and new production orders for steady machine operation.

- Conduct visual and dimensional inspections using microscopes, micrometers, calipers, pin gauges, thread gauges, comparators, Micro-Hite, CMM, and vision systems.

- Perform scheduled and regular preventive maintenance on equipment.

- Drive problem-solving activities for complex machine or process issues.

- Complete and compile documentation related to quality inspection standards.

- Ensure proper material control, identification, and traceability for conforming and nonconforming materials.

- Support Quality Best Practices and contribute to continuous improvement in GDP/GMP.

- Capable of mentoring and training lower-level machinists.

- Facilitate a continuous improvement in culture and ensure quality and delivery objectives are met.

- Utilize ERP and QMS systems to document and control inspection and traceability activities.

- Maintain safe working conditions and follow occupational safety and health requirements, including PPE guidance.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Education

- Certification from a technical school program or equivalent, directly transferable work experience in a manufacturing or engineering discipline may be accepted.

- Certification from a technical school program is strongly preferred.

Experience

- Minimum of 3-7 years’ experience in a regulated manufacturing environment.

Qualifications

- Experience in Class I, II, and/or III medical device manufacturing within a regulated environment using calibrated equipment and hazardous materials.

- Relevant job experience in regulated manufacturing, with industry experience in aerospace, defense, or automotive.

- Knowledge of and experience with GMP/ISO standards.

- A self-starter capable of working independently and as part of a team, with the ability to collaborate across various functional areas, including R&D, Manufacturing, and QA, to achieve results with minimal guidance.

- Advanced understanding of mechanical equipment usage, care, and inspection processes.

- Ability to use hand-held tools for preventive maintenance, repairs, and tool changes.

- Skilled in reading and understanding of blueprints, specifications, and procedures.

- Detail-oriented with the ability to maintain accuracy and complete tasks promptly.

- Proficient in identifying nonconformances and maintaining organization.

- Intermediate skills in GD&T.

Preferred Skills

- Strong verbal and written English language communication skills.

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Perform repetitive hand and arm movements while lifting up to 20 pounds, including gripping, twisting, and placing components for extended periods, and lifting objects overhead.

- 20/20 vision (assisted or unassisted) required for sorting raw and non-conforming materials. Good dexterity is needed for managing small to medium products.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Ability to sit or stand for prolonged periods.

WEEKEND SHIFT: 20% DIFFERENTIAL 5AM-5PM FRI-SUN

2ND SHIFT: 15% DIFFERENTIAL 5PM-3:30AM

1st shift - No differential

Pay Range: $31.00 - $37.00

Job Features

Summary of Position Reporting to the Operations Supervisor, this position will have direct responsibility for the set-up and manufacture of components within the Swiss machining department. TOMZ manuf...

Summary of Position

Reporting to the Operations Supervisor, this position will have direct responsibility for the manufacturing of components through various basic functions within the Department. TOMZ manufactures parts via high precision metal machining, finishing, assembly, and anodizing processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, operate equipment, and perform visual and dimensional inspections on machine components.

Essential Functions

- Operate and maintain 3-4-5 axis production equipment, including Robo Drills, Mill Turn, and horizontal/vertical mills. Citizen Lathes, Tsugami Lathes, Index multi-spindle lathes.

- Perform visual and dimensional inspections on manufactured components, as required using a microscope, micrometer, caliper, pin gauges, thread gauges, comparator, Micro-Hite, etc.

- Support problem-solving activities for complex machine or process issues.

- Complete and compile documentation related to quality inspection standards.

- Ensure proper material control, identification, and traceability for conforming and nonconforming materials.

- Support Quality Best Practices and contribute to continuous improvement efforts of GDP/GMP.

- Utilize ERP and QMS systems to document and control inspection and traceability activities.

- Must maintain safe working conditions and follow occupational safety and health requirements including Personal Protective Equipment (PPE) guidance and rules.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Experience

- Minimum of 0-2 years’ experience in a regulated manufacturing environment.

Qualifications

- Basic understanding of the usage and care of mechanical equipment and inspection processes.

- Ability to use hand-held tools for preventive maintenance, repairs, and tool changes.

- Ability to effectively read and understand blueprints, specifications, and procedures.

- Detail-oriented with the ability to maintain accuracy and complete tasks promptly.

- Basic understanding of GD&T.

- Knowledge of GMP/ISO standards.

Preferred Skills

- Class I, II and/or III Medical Device manufacturing experience.

- Regulated manufacturing industry experience (e.g., aerospace, defense, pharmaceutical, etc.)

- Strong verbal and written English language communication skills.

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Perform repetitive hand and arm movements while lifting up to 20 pounds, including gripping, twisting, and placing components for extended periods, and lifting objects overhead.

- 20/20 vision (assisted or unassisted) required for sorting raw and non-conforming materials. Good dexterity is needed for managing small to medium products.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Ability to sit or stand for prolonged periods.

Summary of Position Reporting to the Operations Supervisor, this position will have direct responsibility for the manufacturing of components through various basic functions within the Department. TOM...

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive compensation and excellent benefits, including 401k, health/dental, vision, and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and certified to ISO 13485.

Summary of Position

Reporting to the Operations Supervisor, this position will have direct responsibility for the set-up and manufacture of components within a machining Department. TOMZ manufactures parts via high- precision metal machining, finishing, assembly, and anodizing processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, set up and operate equipment, and perform visual and dimensional inspections on machined components using various precision measuring equipment.

Essential Functions

- Set up and operate and maintain Citizen Lathes or Tsugami Lathes

- Perform offsets and tool changes to ensure efficient production with minimal support.

- Set up legacy components and new production orders for steady machine operation.

- Perform preventative maintenance on Swiss Lathe to ensure consistent machine performance

- Conduct visual and dimensional inspections using microscopes, micrometers, calipers, pin gauges, thread gauges, comparators, Micro-Hite, CMM, and vision systems.

- Perform scheduled and regular preventive maintenance on equipment.

- Drive problem-solving activities for complex machine or process issues.

- Complete and compile documentation related to quality inspection standards.

- Ensure proper material control, identification, and traceability for conforming and nonconforming materials.

- Support Quality Best Practices and contribute to continuous improvement in GDP/GMP.

- Utilize ERP and QMS systems to document and control inspection and traceability activities.

- Maintain safe working conditions and follow occupational safety and health requirements, including PPE guidance.

Qualifications:

Education

- High school diploma, GED, or equivalent directly transferrable work experience (Manufacturing or Engineering discipline preferred).

- Certification from a technical school program preferred.

Experience

- Minimum of 2-5 years’ experience in a regulated manufacturing environment.

Qualifications

- Experience in Class I, II, and/or III medical device manufacturing within a regulated environment using calibrated equipment and hazardous materials.

- Strong math background, preferable in machine math/shop math

- Relevant job experience in regulated manufacturing, with industry experience in aerospace, defense, or automotive.

- Knowledge of and experience with GMP/ISO standards.

- A self-starter capable of working independently and as part of a team, with the ability to collaborate across various functional areas, including R&D, Manufacturing, and QA, to achieve results with guidance.

- Understanding of mechanical equipment usage, care, and inspection processes.

- Ability to use hand-held tools for preventive maintenance, repairs, and tool changes.

- Effectively read and understand blueprints, specifications and procedures.

- Understanding of GD&T.

- Detail-oriented with the ability to maintain accuracy and complete tasks promptly.

- Identify nonconformances and maintain organization.

Preferred Skills

- Strong verbal and written English language communication skills.

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Perform repetitive hand and arm movements while lifting up to 20 pounds, including gripping, twisting, and placing components for extended periods, and lifting objects overhead.

- 20/20 vision (assisted or unassisted) required for sorting raw and non-conforming materials. Good dexterity is needed for managing small to medium products.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Ability to sit or stand for prolonged periods

1st shift: 6AM-2:30PM

2nd shift: 5PM-1:30AM (15% SHIFT DIFFERENTIAL)

Weekend shift: 6AM-6PM (20% SHIFT DIFFERENTIAL)

Job Features

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a motivated CNC Machinist to join our organization. TOMZ offers competitive com...

Come join us at our newest facility in Big Lake, Minnesota!

Summary of Position

Reporting to the Quality Engineering Manager, this position will be responsible for the activities associated with Quality Design & Development (QD&D) Control and Assurance during Product Development Process (PDP) activities as well as continuation design & development support for sustaining manufacturing and product distribution.

Essential Functions

- Develop and execute Quality Plans for Quality Product Design and Development projects.

- Collaborate with engineering teams to initiate and support the development and updates of Risk Management documentation in accordance with project requirements.

- Establish severity and risk-based Process Master Validation Plan strategies with appropriate V&V rationales.

- Support operational and process qualifications for customer manufacturing processes in collaboration with engineering teams.

- Drive Test Method development with Operational and Business considerations and execution of Test Method Validations to measure effectiveness.

- Implement inspection plans for Incoming, In-Process and Final Product.

- Develop and justify appropriate sampling plans with characterization of test and inspection methods.

- Represent Quality Engineering in design reviews.

- Support initial qualification audit activities for Customer and Regulatory Agencies.

- Support qualification activities related to supplier and vendor design characterization requirements for projects, including conducting audits and assessments.

- Support Quality Best Practices and contribute to continuous improvement in GDP/GMP.

- Apply sound, systematic problem-solving methods in identifying, prioritizing, communicating, and resolving quality issues.

- Ensure that all site personnel comply with the site-level Quality Management System and training requirements.

- Support the development of Quality Agreements for external customers.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Education

- Minimum 4-Year degree or equivalent of directly transferrable industry work experience (Engineering or Quality discipline preferred).

Experience

- Minimum of 2-5 years’ experience in a regulated manufacturing environment.

- Experience in Class I, II, and/or III medical device manufacturing within a regulated environment (e.g., Aerospace, Defense, Pharmaceutical, etc.).

Qualifications

- Advanced Post-Secondary Education, Training or Certification coursework.

- Knowledge of statistical techniques to analyze process capability.

- Quality certification(s) (e.g., ASQ CQE, QCI, etc.).

- Skilled in First Article Inspections and Component Qualifications.

- Knowledge and experience with external standards: ISO 900/9001, ISO 13485, and 21CFR 820, EU MDR, pertaining to product development, design controls, good manufacturing practices, supplier qualification, auditing, quality control (GD&T, Nonconforming Materials, MRB), Corrective and Preventive Actions, and customer complaints).

- Experience in effectively supporting audits by customers and external regulatory agencies.

- Strong verbal and written English language communication skills.

- Successfully meet TOMZ-specific positional and functional on-the-job training requirements.

- Proficiency with Microsoft Office.

- A self-starter capable of working independently and as part of a team, with the ability to collaborate across various functional areas, including R&D, Manufacturing, and QA, to achieve results.

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Ability to sit for prolonged periods.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Perform keyboard entries with frequent operation of a computer.

Come join us at our newest facility in Big Lake, Minnesota! Summary of Position Reporting to the Quality Engineering Manager, this position will be responsible for the activities associated with Quali...

Summary of Position

Reporting to the Quality Engineering Manager, this position will be responsible for the activities associated with Quality Design & Development (QD&D) Control and Assurance during Product Development Process (PDP) activities as well as continuation design & development support for sustaining manufacturing and product distribution.

Essential Functions

- Develop and execute Quality Plans for Quality Product Design and Development projects.

- Collaborate with engineering teams to initiate and support the development and updates of Risk Management documentation in accordance with project requirements.

- Establish severity and risk-based Process Master Validation Plan strategies with appropriate V&V rationales.

- Support operational and process qualifications for customer manufacturing processes in collaboration with engineering teams.

- Drive Test Method development with Operational and Business considerations and execution of Test Method Validations to measure effectiveness.

- Implement inspection plans for Incoming, In-Process and Final Product.

- Develop and justify appropriate sampling plans with characterization of test and inspection methods.

- Represent Quality Engineering in design reviews.

- Support initial qualification audit activities for Customer and Regulatory Agencies.

- Support qualification activities related to supplier and vendor design characterization requirements for projects, including conducting audits and assessments.

- Support Quality Best Practices and contribute to continuous improvement in GDP/GMP.

- Apply sound, systematic problem-solving methods in identifying, prioritizing, communicating, and resolving quality issues.

- Ensure that all site personnel comply with the site-level Quality Management System and training requirements.

- Support the development of Quality Agreements for external customers.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Education

- Minimum 4-Year degree or equivalent of directly transferrable industry work experience (Engineering or Quality discipline preferred).

Experience

- Minimum of 2-5 years’ experience in a regulated manufacturing environment.

- Experience in Class I, II, and/or III medical device manufacturing within a regulated environment (e.g., Aerospace, Defense, Pharmaceutical, etc.).

Qualifications

- Advanced Post-Secondary Education, Training or Certification coursework.

- Knowledge of statistical techniques to analyze process capability.

- Quality certification(s) (e.g., ASQ CQE, QCI, etc.).

- Skilled in First Article Inspections and Component Qualifications.

- Knowledge and experience with external standards: ISO 900/9001, ISO 13485, and 21CFR 820, EU MDR, pertaining to product development, design controls, good manufacturing practices, supplier qualification, auditing, quality control (GD&T, Nonconforming Materials, MRB), Corrective and Preventive Actions, and customer complaints).

- Experience in effectively supporting audits by customers and external regulatory agencies.

- Strong verbal and written English language communication skills.

- Successfully meet TOMZ-specific positional and functional on-the-job training requirements.

- Proficiency with Microsoft Office.

- A self-starter capable of working independently and as part of a team, with the ability to collaborate across various functional areas, including R&D, Manufacturing, and QA, to achieve results.

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Ability to sit for prolonged periods.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Perform keyboard entries with frequent operation of a computer.

Pay Range: $79K - $108K / year

Summary of Position Reporting to the Quality Engineering Manager, this position will be responsible for the activities associated with Quality Design & Development (QD&D) Control and Assurance...

TOMZ Corporation, a leader in the manufacturing of devices and components for major medical device companies, is looking for a Human Resources Assistant to join our organization. TOMZ offers competitive compensation and excellent benefits, including 401k, health/dental, vision and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and is certified to ISO 13485.

Summary of Position

The HR Generalist will be responsible for applying human resources expertise in several areas of HR and assist in providing a wide range of support to the business. The successful candidate will play a key role in the administration, organization, and success of the HR Department by providing support to the Director and guidance on employee on basic company related information.

*No relocation is being offered for this role.

Essential Functions

- Responsible for new employees on their first day, tasks include taking employee badge photos, verifying paperwork, Orientation and ordering lunch.

- Prepare new hire paperwork, scan, file and track all new hire paperwork.

- Assist employees with questions on various benefits websites; Health Insurance, Safety Shoes, and TOMZ Apparel.

- Ensure that all new hire onboarding paperwork, transfer and promotion paperwork is completed and turned in on time.

- Administer employee referral bonuses.

- Audit and track all employee paperwork for compliance.

- Handles administrative tasks for department, files and processes terminations related to employee files.

- Understand Form I-9, maintain historical I-9’s and assist with obtaining new documentation as needed.

- Assist Employee Relations Specialist with the community projects and programs such as employee recognition, wellness, and company events.

- Post and distribute internal communications, information, and materials.

- Maintain employee bulletin board, Wellness Board and Anniversary Board in CT.

- Maintains and updates OSHA Log.

- Able to back-up to assist with Recruiting as necessary.

If Bi-lingual:

- Will be responsible for coordinating and conducting HR Orientation, Safety Orientation and Quality Systems Orientations.

- Translate other employee questions as necessary.

- Must be knowledgeable of, and adhere to, the TOMZ Quality Management System. Responsible for compliance of Human Resources records in relationship the Quality Management System.

- Other duties as assigned.

Qualifications:

Education and Experience

- Bachelor’s degree in human resources or relevant experience.

- 5+ years in a Generalist Role.

Qualifications

- Ability to maintain confidentiality and professionalism.

- Proficiency with Microsoft Office (Microsoft Excel, Microsoft Outlook, Microsoft PowerPoint).

- Understanding of personnel and compliance records management.

- Excellent written, verbal, and interpersonal communication skills.

- Strong level of attention to detail.

- Ability to work independently or collaboratively.

Preferred Skills

- Highly preferred: Bi-lingual in Ukrainian and Polish languages.

- OSHA reporting compliance.

Pay Range: $27 - $38 / hour

TOMZ Corporation, a leader in the manufacturing of devices and components for major medical device companies, is looking for a Human Resources Assistant to join our organization. TOMZ offers competiti...

Summary of Position

Reporting to the Quality Manager this position will be responsible for the activities associated with quality engineering in a medical device manufacturing environment. This includes but is not limited to assessing process risk and implementing appropriate control mechanisms, corrective and preventative action, and creating and refining test methods.

Essential Functions

- Operates and programs advanced measurement equipment including Vision Systems and CMMs.

- Authors Inspection Plans and defines process controls.

- Collaborates and defines Test Method.

- Knowledge of precision measuring instruments and their application, including but not limited to, calipers, micrometers, depth gages, indicators, and plug and thread Go gages and No-Go gages.

- Execution and evaluation of Test Method Validations.

- Support the creation of production visual standards and standardized acceptance criteria for TOMZ’s manufacturing processes.

- Initiate and consult in the development and update of Risk Management documentation in cooperation with cross-functional engineering teams per project requirements.

- Collaborates to develop Process Master Validation Plans.

- Performs process qualifications, analyzes data and initiates corrections or corrective actions as required.

- Provides hands on direction for executing Incoming, In-Process and Final Product Inspection plans.

- Champion First Article Inspections.

- Support Gage calibration review, management, execution and evaluation.

- Support and enforce Quality Best Practices and GDP/GMP continuous improvement efforts.

- Apply sound, systematic problem-solving methodologies in identifying, prioritizing, communicating, and resolving quality issues through the CAPA process.

- Support the tracking and reporting of inspection data, including but not limited to rejection rates, defect modes and process trends across customers and product families.

- Generate ECOs for the release of Quality Engineering documentation.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Education

- Bachelor's or higher degree in Engineering, Manufacturing, or Business discipline or equivalent of directly transferable industry work experience.

Experience

- Minimum of 0-2 years’ experience in a regulated manufacturing environment.

- Prior relevant internship experience preferred.

Qualifications

- Demonstrated self-starter with ability to work in a fast-paced environment.

- Competency with Microsoft Office (i.e. Outlook, Word, Excel, and PowerPoint)

- Strong verbal and written English language communication skills.

- Basic understanding of statistical techniques and sampling strategies

Preferred Skills

- ASQ-CQT, CQE or CRE preferred.

- Certification in GD&T preferred

- Certifications in DMIS programming preferred

- Class I, II and/or III Medical Device manufacturing experience.

- Regulated manufacturing industry experience (e.g. Aerospace, Defense, Pharmaceutical, etc.)

Travel Requirements

- Travel outside the workplace is required for up to 15% of the year.

- Travel may include multiple overnight stays and may occasionally require weekend commitments.

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 30 pounds. Team lift or mechanical assistance required for objects over 30 pounds.

- Ability to sit for prolonged periods.

- Exposure to oil, grease, occupational noise, cleaning solvents, dust, metal particles, sparks, coolant, and sharp-edged materials. Personal protective equipment (PPE) such as safety glasses, dust masks, ear plugs, cut-resistant or chemical-resistant gloves, and engineering controls may be required.

- Perform keyboard entries with frequent operation of a computer.

Pay Range: $65K - $96K / year

Summary of Position Reporting to the Quality Manager this position will be responsible for the activities associated with quality engineering in a medical device manufacturing environment. This includ...

Summary of Position

Reporting to the Department Manager, this position will have direct responsibility for the processing of parts through various functions within the Department. TOMZ manufactures parts via high precision metal machining, finishing, assembly, and anodize processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation, prepare materials to be processed through various operations, and perform basic visual and dimensional inspections on completed components.

Essential Functions

- Prepare and process components through various metal finishing operations.

- Tumbling

- Blasting

- Heat Treat

- Laser Welding

- Laser Marking

- Passivation

- Anodize

- Perform visual and basic dimensional inspections on completed components, as required using micrometers, calipers, microscope, etc.

- Completes and compiles necessary documentation related to Quality Inspection standards.

- Ensure proper material control, identification and traceability is maintained for conforming and nonconforming material through the manufacturing processes.

- Support Quality Best Practices and GDP/GMP continuous improvement efforts.

- Utilize and navigate ERP and QMS systems to ensure inspection and traceability activities are properly documented and controlled, as needed.

- Must follow occupational Safety and Health requirements including Personal Protective Equipment (PPE) guidance and rules.

- Other duties and responsibilities are assigned.

Qualifications:

Education

- High school diploma, GED, or equivalent directly transferrable work experience (Manufacturing or Engineering discipline preferred).

Experience

- Minimum of 0-2 years’ experience in a regulated manufacturing environment.

Qualifications

- Ability to use basic hand-held tools to support preventive maintenance activities.

- Maintains accuracy and attention to detail at all times and completes tasks in a timely manner.

- Strong verbal and written English language communication skills.

- Strong background concerning the usage and care of mechanical metal finishing equipment and processes.

- Must have good organizational skills.

Preferred Skills

- Ability to effectively read and understand blueprints, specifications, and procedures.

- Knowledge of and experience with GMP/ISO standards.

- Regulated manufacturing industry experience (e.g. Aerospace, Defense, Pharmaceutical, etc.)

- Class I, II and/or III Medical Device manufacturing experience.

Physical Demands

While performing the duties of this job, the employee is frequently required to sit, talk and/or hear, and/or use hands to finger, handle, or touch objects, tools, or controls. The employee is frequently required to stand, and/or walk. The employee must occasionally lift and/or move up to 50 pounds while moving components or fixtures/racking. The mental and physical requirements described here are representative of those that must be met by an individual to successfully perform the essential functions of this position.

Summary of Position Reporting to the Department Manager, this position will have direct responsibility for the processing of parts through various functions within the Department. TOMZ manufactures pa...

Summary of Position

Support the organization’s Turning Milling and Grinding operations of complex medical devices through new development projects as well as optimization of existing legacy programs. Work in cross functional teams to drive continuous improvement and ensure production objectives are met; including but not limited to programming for new product development, optimization of legacy programs for improved throughput, standardization of programs to current best practices, and research and implementation of new tooling and process technology. Creating 1st pc and in- process inspection plans, process validations, equipment specification for production line-up and fixturing design.

Essential Functions

Duties and responsibilities include, but are not limited to:

- Ability to program various pieces of CNC equipment across multiple sites as directed to support critical and/or high-value projects milling, turning, and grinding, Multi spindle, Multi Axis and Swiss style programs for manufacture of medical devices- implants and instruments.

- Analyze drawings, design models, and sketches to determine dimensions and configuration of cuts, selection of cutting tools, machine speeds, and feed rates according to shop processes, customer specifications, and machine capabilities.

- Actively participate in process development projects and DFM with internal and external teams

- Revise programs to eliminate instruction errors, omissions, and update programs with new technology/methods to improve efficiency; meet customer delivery dates

- Coordinate with Quality Engineering to help facilitate the development of Process Control Plans, Manufacturing Inspection Plans, and gaging/fixturing requirements.

- Create 1st pcs and in-process inspection plans.

- Design fixtures for post processing operations.

Qualifications:

Education

- Associate degree in technical or scientific field or equivalent work experience.

Experience

- Minimum of 5 years’ experience of programming in a medical device manufacturing environment or similar

Preferred Skills/Qualifications

- Strong knowledge of NC Code, Tooling, and Manufacturing Process.

- Knowledge of CAD/CAM software (SolidWorks and Esprit preferred)

- Blueprint reading and knowledge of Geometric Dimensioning and Tolerancing (GD&T)

- Effective communication to all levels of internal and external customers

- Ability to apply logic and reasoning to solve complex problems.

Pay Range: $69,000 - $125,000 a year

Summary of Position Support the organization’s Turning Milling and Grinding operations of complex medical devices through new development projects as well as optimization of existing legacy programs...

Summary of Position

Reporting to the Quality Manager, this position will have direct responsibility for the quality control functions within the Department. TOMZ manufactures parts via high precision metal machining, assembly, and anodize processes for Medical Devices. The successful candidate will be expected to maintain the ISO 13485 standards documentation and perform inspections on machined components by utilizing conventional layout inspection techniques and equipment.

Essential Functions

- Train and perform inspections on machined components, utilizing conventional visual and layout inspection techniques and equipment. Ex. include microscopes, calipers, micrometers, and gages.

- Train and perform further complex inspections on machined components utilizing methods such as comparators, CMM, various manual and automated techniques.

- Demonstrate team leadership, train, and provide guidance to Quality Control personnel.

- Execute Incoming, First Piece, FAI, In-process, and Final Inspection, as assigned.

- Creates, completes, and compiles necessary documentation related to Quality Inspection standards.

- Provide basic programming assistance for complex inspection and test methods, as required.

- Ensure proper material control, identification and traceability is maintained for conforming and nonconforming material through the manufacturing processes.

- Ensure and enforce a thorough review and adherence to Good Document Practices (GDP) for Routers, Inspection plans, and Device History Records (DHRs) throughout the manufacturing process and in preparation for the final lot release and shipment.

- Support Quality Best Practices and GDP/GMP continuous improvement efforts.

- Utilize and navigate ERP and QMS systems to ensure inspection and traceability activities are properly documented and controlled, as needed.

- Utilize the ERP system to prioritize and support product final acceptance and shipment, as needed.

- Generate Packing Slips and Certificates of Compliance (C of C) in accordance with TOMZ and customer requirements.

- Support physical and electronic record retention.

- Must follow occupational Safety and Health requirements including Personal Protective Equipment (PPE) guidance and rules.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Education

- High school diploma, GED, or equivalent directly transferrable work experience (Manufacturing or Engineering discipline preferred).

Experience

- Minimum of 5-7 years’ experience in a regulated manufacturing environment.

Qualifications

- Quality certification(s) (e.g., ASQ CQT, QCI, etc.).

- Class I, II and/or III Medical Device manufacturing experience.

- Regulated manufacturing industry experience (e.g., Aerospace, Defense, Pharmaceutical, etc.)

- Knowledge of and experience with GMP/ISO standards.

- Strong background concerning the usage and care of mechanical measurement equipment, tools and hand-held tools including micrometers, calipers, dial indicators, height gages, pin gages, etc.

- The ability to effectively read and understand blueprints, specifications and procedures.

- Maintains accuracy and attention to detail at all times and completes tasks in a timely manner.

- Knowledge of dimensional, visual, and mechanical inspection processes.

- Competency with Microsoft Office.

- “Hands-on” self-starter with ability to work both independently and as part of a team.

- Ability to work with a variety of functional areas, including R&D, Manufacturing, and QA, as required, accomplishing results with minimal guidance.

- Strong verbal and written English language communication skills.

Summary of Position Reporting to the Quality Manager, this position will have direct responsibility for the quality control functions within the Department. TOMZ manufactures parts via high precision ...

We are hiring!! TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a highly motivated Facilities Technician I to join our organization! Founded in 1988, TOMZ continues to be a family owned and operated organization which offers competitive compensation and excellent benefits. Those include 401k, health/dental, vision, and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and is certified to ISO 13485.

Summary of Position

Reporting to Facilities Manager, this position will have direct responsibility for basic preventive maintenance, repairs and improvements of all support equipment around the facility. TOMZ manufactures parts via high precision metal machining, finishing, assembly, and anodize processes for Medical Devices. The successful candidate will be expected to maintain the highest level of cleanliness and safety possible in support of our mission to foster a desirable work environment for all employees and guests to our facility.

Essential Functions

- Perform basic routine preventive maintenance and cosmetic improvement activities in various areas of the facility. Ex. Touch-up painting, hanging TV’s/whiteboards/operational displays, etc.

- Frequent operation of the floor cleaning machine to maintain a safe working/walking surface throughout all machining areas. Occasional mopping between machines.

- Routine cleaning of Offices, post machining and inspection areas per schedule and as needed.

- Trash removal from all operational areas of the facility.

- Help with performing repairs, maintenance on plumbing, Electrical, HVAC, and other systems.

- Perform full machine cleanouts to remove chips and change coolant.

- Operation of the Chip Spinner to reclaim coolant and separate from metal chips.

- Must follow occupational Safety and Health requirements including Personal Protective Equipment (PPE) guidance and rules.

- Other duties and responsibilities are assigned.

Qualifications:

Education

- High school diploma, GED, or equivalent directly transferrable work experience (Manufacturing or Engineering discipline preferred).

Experience

- Minimum of 1-3 years’ experience in facilities maintenance.

Qualifications

- “Hands-on” self-starter with ability to work both independently and as part of a team.

- Maintains accuracy and attention to detail at all times and completes tasks in a timely manner.

- Ability to use basic hand-held tools to support maintenance activities.

- Forklift and OSHA training required.

TOMZ is an Equal Opportunity Employer

We are hiring!! TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a highly motivated Facilities Technician I to join our organiza...

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a highly motivated Shipping and Receiving Technician to join our organization! Founded in 1988, TOMZ continues to be a family owned and operated organization which offers competitive compensation and excellent benefits. Those include 401k, health/dental, vision, and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and is certified to ISO 13485.

Summary of Position

Reporting to the Supply Chain Manager, this position is responsible for supporting operations with product flow as needed. TOMZ corporation, a company specializing in high-precision metal machining, finishing, assembly, and anodizing for Medical Devices. The successful candidate will maintain the highest level of traceability in handling the receipt, storage, and issuance of raw materials, ensuring smooth support for manufacturing processes while adhering to regulatory and quality standards.

Essential Functions

- Receipt and incoming inspection of all raw materials.

- Appropriate storage of all raw materials including ERP transactions and physical locations.

- Issue raw materials to manufacturing operations.

- Perform and document routine cycle counts to ensure proper inventory levels are maintained.

- Print Job Travelers as required to support production flow.

- Perform the “SAW” operation for all required materials prior to issuing to production floor.

- Ensure proper material control, identification and traceability is maintained for conforming and nonconforming material through the manufacturing processes.

- Monitor and order office and shop supplies.

- Order production tooling and enter into inventory when received.

- Support manufacturing as needed.

- Adhere to the TOMZ Quality Management System.

- Perform other duties as assigned.

Qualifications:

Education

- High school diploma, GED, or equivalent directly transferrable work experience (Manufacturing or Engineering discipline preferred).

Experience

- Minimum of 2-5 years’ experience in a regulated manufacturing environment.

Qualifications

- “Hands-on” self-starter with ability to work both independently and as part of a team.

- Demonstrated ability to manage inventory levels.

- Maintains accuracy and attention to detail at all times and completes tasks in a timely manner.

- Ability to use basic hand-held tools and inspection equipment to support receiving inspection activities.

- Forklift training required.

Physical Demands

- Ability to bend, stoop, squat, kneel, and lift up to 50 pounds. Team lift or mechanical assistance required for objects over 50 pounds.

- Perform keyboard entries with possible frequent operation of a computer.

- Ability to use power tools as needed.

- As needed to comply with safety requirements - need to wear safety equipment such as cut resistant gloves, safety glasses, hearing protection, steel toe and slip resistant shoes.

Pay Range: $21/hr - $28/hr

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a highly motivated Shipping and Receiving Technician to join our organization! ...

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a Senior Machine Maintenance Specialist to join our organization. TOMZ offers competitive compensation and excellent benefits, including 401k, health/dental, vision, and paid time off. TOMZ maintains a modern, clean, and safe facility with state-of-the-art equipment and dedication to continuous process improvement. TOMZ is registered with the FDA as a Class 2 and Class 3 Medical Device Manufacturer and is certified to ISO 13485.

Summary of Position

The purpose of the Senior Machine Maintenance Specialist is to provide production equipment support for all equipment allocated to the Factory as well as to assist engineering with production-related projects. Routinely works with Plant Maintenance to coordinate jobs and projects. The Senior Machine Specialist will take the lead in the implementation and the decision-making process on best practices for the maintenance group. The position is also responsible for creating solutions and providing technical support to enhance production reliability through concerted efforts with cross functional teams.

Essential Functions

Duties and responsibilities include, but are not limited to:

- Adherence to all department safety measures and work instructions.

- Accountable for personal safety, the safety of co-workers and promoting a safe work environment.

- Repair and maintain all production equipment, both electrical and mechanical.

- Assist engineering as required with special machine related projects.

- Work with CONC and PLC controlled machines.

- Routinely work in electrical control panels of production equipment to troubleshoot electrical problems.

- Arc Flash certified worker to work “live” electrical control panels.

- Working understanding of precision measuring instruments used in troubleshooting.

- Read and interpret diagrams, schematics and specifications related to equipment operation.

- Monitor, modify, or write programmable ladder logic circuits as needed for existing or new installations.

- Create electrical drawings, PLC programs to be used for troubleshooting of modified equipment.

- Install electrical, air and data drops to equipment and machines.

- Work with outside contractors for equipment repair of production machines as needed and verify completion accuracy.

- Design and implement electrical circuits and technologies for support of production equipment.

- Initiate or enhance the preventative maintenance schedules for production equipment.

- Calibrate equipment using general and special purpose test equipment.

- Facilitate equipment modifications, upgrades, overhauls, and root cause failure analyses.

- Ensure respective area is complaint with 5S Standards.

- Maintain daily log of work in established systems.

- Support ISO 13485 initiatives.

- Assist in training individuals with less experience and tenure on established maintenance standards and practices.

- Project initiation and improvement ideas to better production and the business.

- Purchase repair parts, tools, and supplies in appropriate ERP software.

- Provide input for annual department budget planning.

- Ability to work flexible hours (including overtime) to accommodate production working hours as needed.

- Other duties and responsibilities as assigned.

Qualifications:

Education

- Associate degree in a technical related field or equivalent experience

Experience

- Minimum 10 years’ experience in the Equipment Maintenance Field

Qualifications

- “Hands-on” self-starter with ability to work both independently and as part of a team.

- Maintains accuracy, is detail oriented, and completes tasks in a timely manner.

- Prior experience with CNC and PLC controlled equipment.

- Experience with MS Office Programs.

- Ability to perform routine maintenance of CNC manufacturing equipment; troubleshoot issues and support, or directly resolve as appropriate.

- Ability to read and interpret documents and drawings (e.g., blueprints, manuals, wiring diagrams etc.)

- Time management skills and ability to prioritize workflow throughout the day.

- Strong verbal and written English language communication skills.

Preferred Skills

- Forklift and OSHA Training.

Physical Demands

While performing the duties of this job, the employee is frequently required to sit, talk and/or hear, and/or use hands to finger, handle, or touch objects, tools, or controls. The employee is frequently required to stand, and/or walk. The employee must occasionally lift and/or move up to 50 pounds while moving tooling, fixtures, equipment and/or small packages. The mental and physical requirements described here are representative of those that must be met by an individual to successfully perform the essential functions of this position.

Pay Range: $29.81/hr - $43.75/hr

TOMZ Corporation, a leader in manufacturing of devices and components for major medical device companies, is looking for a Senior Machine Maintenance Specialist to join our organization. TOMZ offers c...

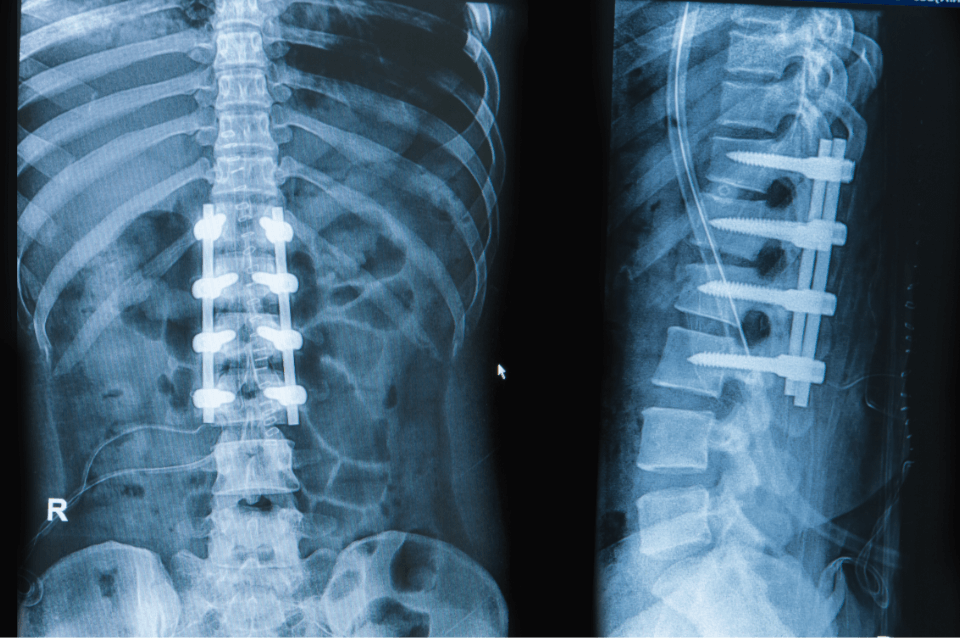

Our Mission

Advancing quality of life by manufacturing medical devices for global healthcare companies.

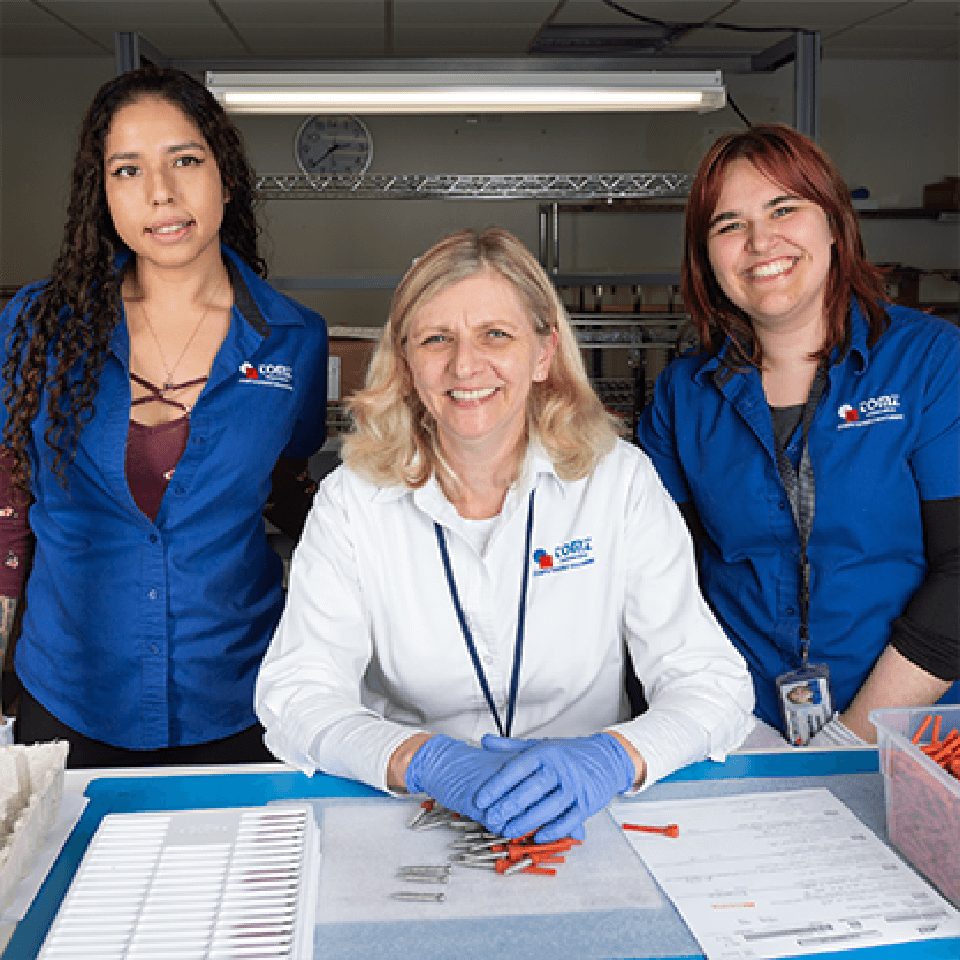

We Manufacture Medical Devices

We specialize in manufacturing the best medical device implants for medical teams and surgeons around the world. Most of our team will tell you that the work is very fulfilling because we help people live better lives.

Company Values & Culture

Our DNA is as unique as everyone that works here.

Put Patients First

Embrace Diversity

Learn & Grow

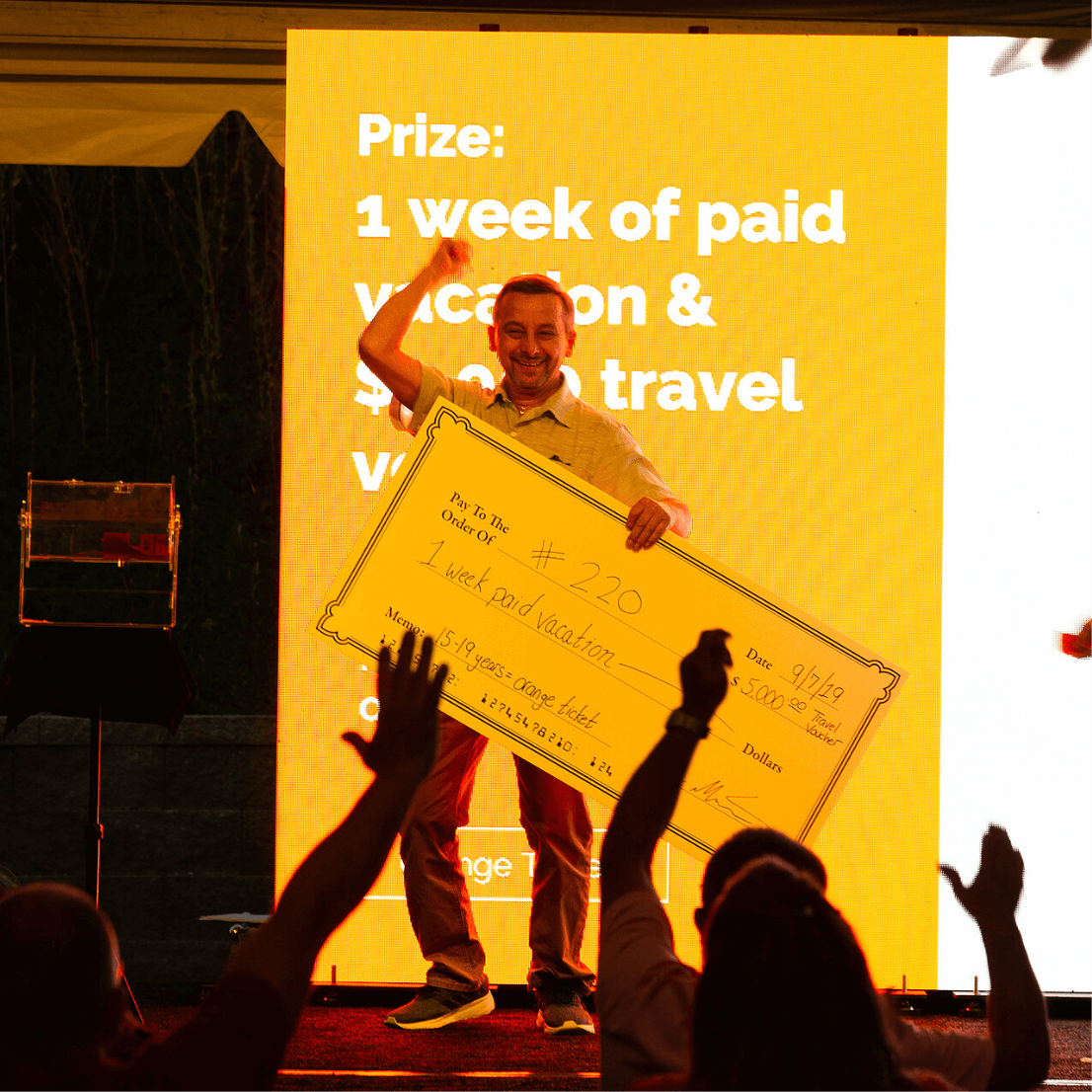

Reward Great Effort

Why Work at TOMZ?

We are large enough to offer stability and great benefits, yet small enough to recognize you as an individual and not just “another employee.”

Multiple departments from facilities management to engineering allows you to explore different career paths.

The medical devices industry is experiencing explosive growth with no signs of stopping any time soon.

We have completed our 8th expansion which includes amenities such as locker rooms, showers, an expanded cafeteria, and more.

We have a deep bench of knowledgeable pros to help you.

Everything from 401K to top-of-the-line healthcare, life insurance, and more!

What Our Team Members Have to Say

Playlist

2:37

2:12

Benefits

401(k) Retirement Plan

We will match $0.50 on the dollar up to an 8% contribution. Work with us, retire with us.

Overtime Available

Opportunities to earn overtime hours are available as needed.

Paid Holidays

Enjoy 9 paid holidays off per year.

Paid Time Off (PTO)

PTO starts accruing from the day you start.

Referral Bonus

Employees are eligible to earn a $3,500 referral bonus!

Health Insurance Plans

Enjoy a low employee co-pay with high contributions towards your plan.

Dental Insurance Plans

Yes - we have a great dental plan as well!

Quarterly Bonus

Teams achieving set performance goals receive a quarterly performance bonus.